2021 has seen strains and extreme tightening on raw materials within the adhesive industry and across many other industries. But what’s driving these raw material shortages?

- Q1 2020 saw the start of the COVID-19 global pandemic

- Q2 2020 saw global demand for raw material drop due to COVID-19 and suppliers reduced production

- Q3 2020 saw a sudden increase of demand due to recovery in China, raw material inventories were very low, forcing price movement

- Q4 2020 saw global demand continue to grow with strong supply & demand imbalances on materials and logistics, further price increases applied

- February 2021 saw a massive snowstorm hit US chemical plants resulting in shortages, followed in March 2021 by major disruption in supply chain due to blocked Suez canal. Competing industries for raw materials such as solar, construction and packaging industry have impacted and led to unprecedented raw material supply shortages seen today

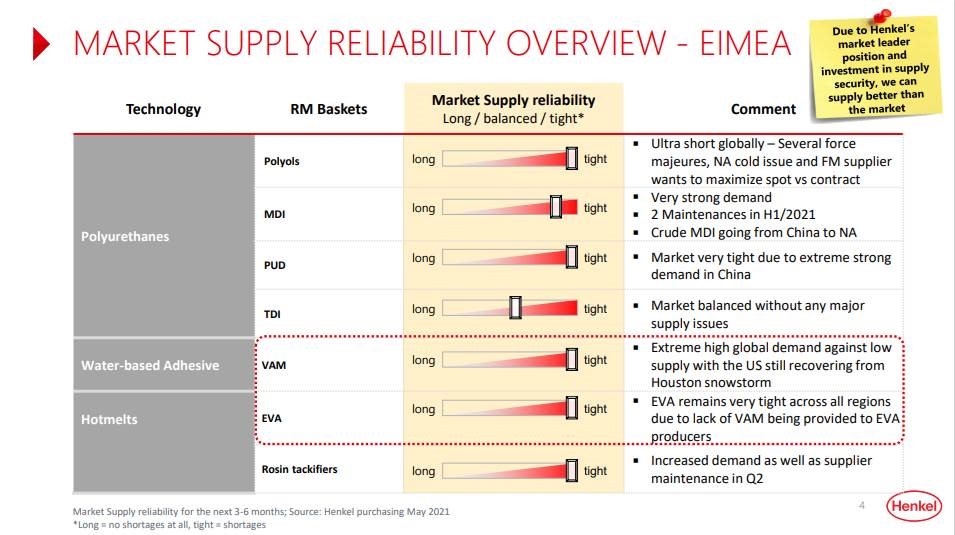

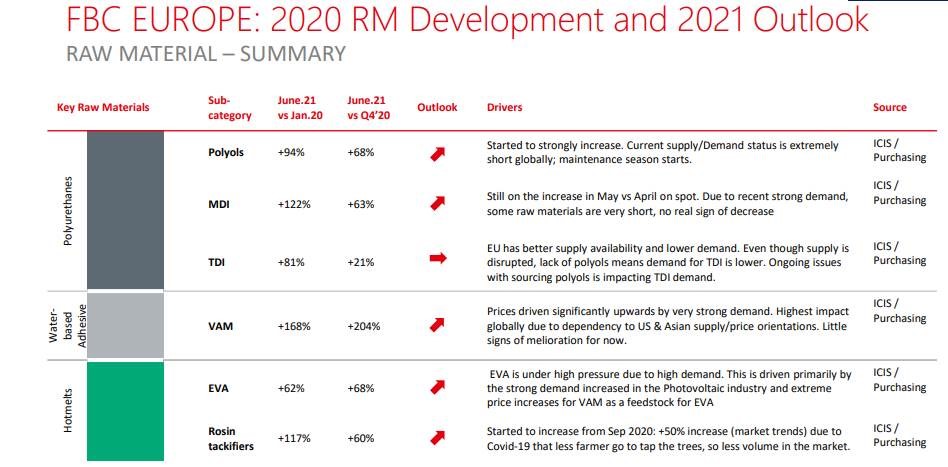

Ian Kenyon, Managing Director for Kenyon’s, goes on to say “Suppliers have applied price increases, Force Majeure, seen supply interruptions and have transport (road, sea and air) worries, which have hindered the movement of goods. It’s not been easy, to say the least, and at times it’s been nerve-wracking. Price increases almost seem to be a weekly occurrence in some sectors. However, price rises are not the key issues frightening industry – product supply is the greatest apprehension, with many customers being placed on allocation or given long delivery dates, which has been seen across many markets and the adhesive industry is not alone in this regard. As 2021 rolls into second half of the year, the adhesive market will continue to face many challenges with raw materials, for example Polyols, MDI and PUD used to manufacture PUR adhesives, VAM, EVA and Rosin Tackifier’s used in water based and hot melt adhesives will continue to be tight and in short supply. However, at Kenyon’s we pride ourselves on the fact that we will keep you gluing! Reinforced and supported by global adhesive giant Henkel, Kenyon’s will not let you down and promise to keep you gluing through these unprecedented times.”

Kenyon’s are proud to be Henkel’s Premium Partner for woodworking and building components

Henkel have given the UK highest emphasis, expressing deliveries as soon as product is available to keep your edgebanders running. Key products, such as Technomelt KS351 unfilled EVA and Technomelt RS270-7 PUR adhesives used extensively for edgebanding, are placed with high priority to ensure continuation of supply. Ian Kenyon says “It’s not been easy and there’s no point beating around the bush, with everything going on globally we are seeing the perfect storm impacting product supply. However, deliveries are filtering through. Unfortunately, we do however have several grades on allocation so that we can have product available for all customers and to a large extent we have successfully secured stock deliveries through our global supply network”

Due to Henkel’s market leader position and investment in supply securities, we can supply better than the market

So, what is the outlook? The current demand-supply mismatch is improving, but some suppliers are sadly taking the position of “take it or leave it” with supply and price increases. Q3 and Q4 2021 will be challenging, difficult and at times thought provoking. Nevertheless, Kenyon’s with Henkel’s might and support will keep you gluing.

Visit: www.kenyon-group.co.uk